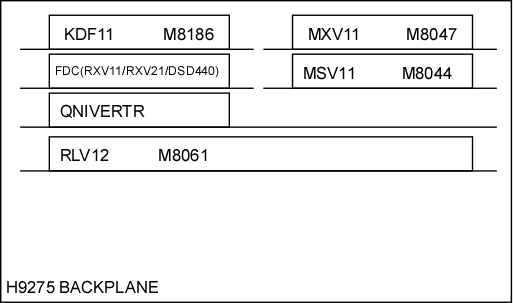

A failure module in the PDP-11/LSI-11 unit makes the system unbootable.

Media

The first step is to check the disk media, floppy disk, or hard disk drive. If you have a stock, please try to replace the media.

Disk controller

The system cannot boot when a disk controller is damaged. If you have both floppy and hard drives, please try to boot from one of them. Please note that the jumper setting of a disk controller and MXV11-A module must be set correctly. DEC module, RLV11, RLV12, RXV11, and RXV21 can be tested using the XXDP. As far as I know, third party modules, DSD4140 and BD-05 are strong enough, and I have never seen a broken module.

The RLV12 RL02 disk controller has several major modes of failure.

(1) VCO

The simple one is the drift of the C65 trimmer capacitor. When the VRLBC0 diagnostic gives many data errors, please try to readjust it. The XXDP RLV12 diskless controller test helps readjustment. Also, E135, 74S124, is sometimes damaged.

(Receiver/Transceiver)

The next one is the damage of transceiver/receiver ICs (75113 and 75107B). If both +5V and -5V supplies are OK, please replace them.

(-5V supply)

Yet another problem related to the transceiver and receiver is the failure of the -5V power supply. RLV12 generates -10V from +12V supply and, then, generates -5V using LM360H.

(Sequencer PROM)

The data in a PROM, E20, E21, E22 (82S171), was sometimes broken. You need to replace the broken PROM with correct data. Only limited ROM writers support SIGNETICS/Philips fused PROM (e.g., TopMAX II). (Similar problem may occur in the VACUUM CONT of the JXA-8800/8900 EPMA. They use SIGNETICS fused PLDs.

(Serious damage)

The last problem makes XXDP give MAINTENANCE MODE SEQUENCER ERROR. I have no idea for reason and solution.

Memory module

A failure of DRAM IC on the MSV11-D module also causes the unbootable problem. If you have another MSV11-D module, please try to replace it. The XXDP memory test helps to identify damaged DRAM IC. The address and data give information on the bank and data bit, respectively.

![[MOD] fix timing problem of 35-DMA](https://oldepma.org/wp-content/uploads/2016/04/35-DMA-mod-300x163.jpg)